Unlocking the Potential: A Stitch-and-Glue Boatbuilding Revolution

Stitch-and-glue boatbuilding, with its inherent simplicity and efficiency, has captivated hobbyists and professionals alike. But are we truly maximizing its potential? This article delves beyond the standard how-to guides, exploring unconventional approaches and fresh perspectives to elevate your stitch-and-glue project to new heights of performance and satisfaction. We'll tackle questions rarely addressed, offering insights for everyone from seasoned craftsmen to enthusiastic beginners.

Beyond the Basics: Rethinking Stitch-and-Glue Design

Traditional stitch-and-glue plans often focus on proven designs. But what if we challenge the norms? What innovative design elements could we incorporate to achieve superior performance without sacrificing the inherent ease of the method?

Q: Can we optimize hull shape for specific water conditions?

A: Absolutely! While many plans offer general-purpose hulls, we can leverage computational fluid dynamics (CFD) software â€" readily available and increasingly user-friendly â€" to design hulls optimized for specific conditions. For example, a flat-bottomed design excels in shallow waters, while a deeper V-hull cuts through waves more efficiently. By modeling various hull forms and analyzing their performance in virtual environments, we can make data-driven design choices for improved speed, stability, and fuel efficiency. This opens up a world of custom boat design, tailoring the vessel to your specific needs rather than adapting your needs to a pre-existing design.

Q: How can we integrate advanced materials beyond plywood?

A: While plywood remains the staple, experimenting with composite materials like fiberglass or carbon fiber reinforcements in strategic areas (e.g., keel, chines) can significantly boost strength and reduce weight, leading to improved performance. This approach requires careful consideration of material compatibility and bonding techniques, but the results can be transformative, particularly in high-performance applications. Recent research in bio-composites (using natural fibers like flax or hemp) also offers sustainable alternatives with potential performance advantages.

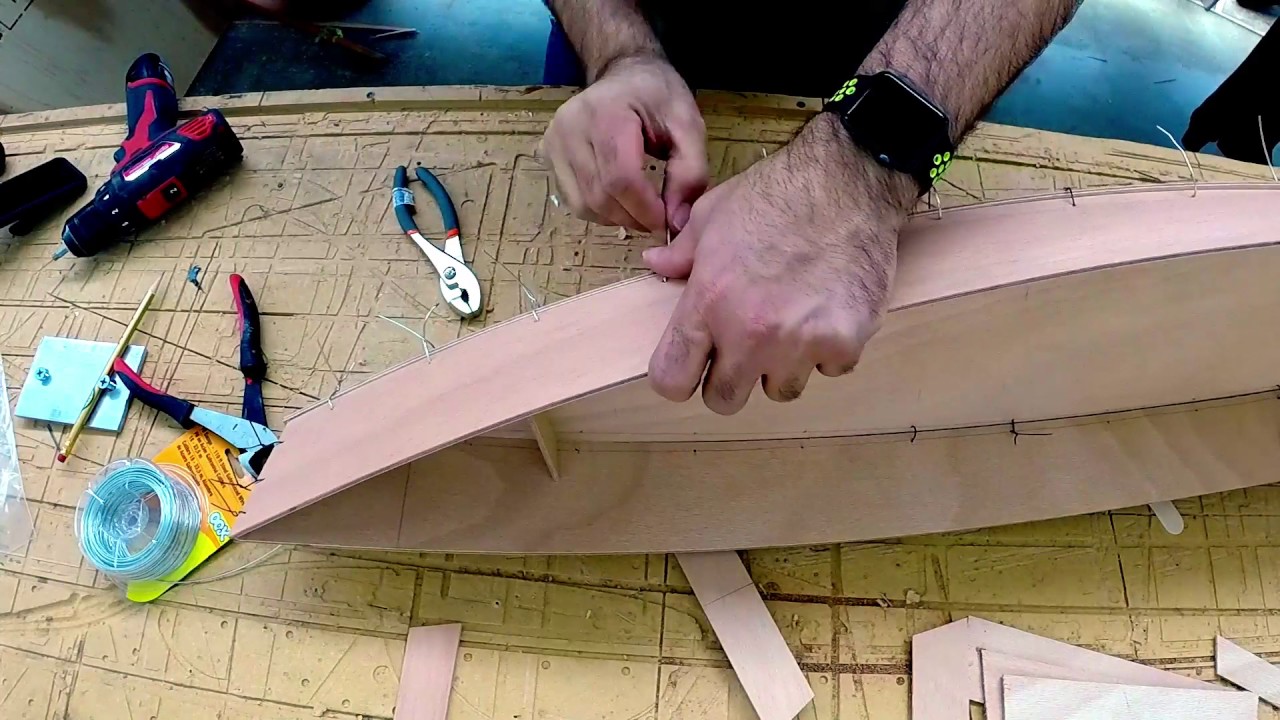

Construction Innovations: Pushing the Envelope

The simplicity of stitch-and-glue is its strength, but we can further streamline the process and improve the final product through smarter techniques.

Q: Can we automate or semi-automate parts of the process?

A: CNC routing offers remarkable precision in cutting plywood parts, drastically reducing labor and improving accuracy. While a CNC router might be a significant investment, consider the time savings and superior quality it provides. For smaller projects or hobbyists, even simple jigs and templates can dramatically increase efficiency and consistency.

Q: How can we improve the epoxy bonding process?

A: Proper epoxy mixing and application are critical. But beyond the basics, exploring techniques like vacuum bagging can eliminate air bubbles and ensure complete saturation of the seams, leading to a stronger, lighter, and more durable hull. This is particularly valuable for larger projects or when using advanced composite materials. Using advanced epoxy formulations with enhanced UV resistance can also prolong the life of your boat.

Real-World Success Stories

The true test of any theory is its practical application. Consider the following anecdotal evidence:

- The "Green Dragon" Project: A group of students at a maritime college used CFD analysis to design a lightweight racing dinghy using stitch-and-glue construction, achieving a surprising performance boost compared to traditional designs.

- The "Eco-Cruiser": A hobbyist builder incorporated recycled materials and sustainable epoxy into his stitch-and-glue sailboat, demonstrating the environmental potential of this building method while achieving a surprisingly robust and seaworthy vessel.

Stitch-and-glue boatbuilding offers a gateway to crafting high-performance vessels, but by embracing innovation and exploring uncharted territories, we can unlock its full potential. The future of stitch-and-glue lies not only in its simplicity but in its capacity for creativity and advancement. Let's push the boundaries and build boats that are not only functional but also a testament to human ingenuity.

0 comments:

Post a Comment